OilN2® - Automatically converts your oil reservoir “open breather vent” into a “closed breather vent” system.

How the OilN2® closed breather vent treatment unit works.

OilN2® is a high-performance hydraulic oil protecting system that replaces traditional oil reservoir open breather vents with filters or filter/dryer breathers.

OilN2® uses a bladder, heat pipe, desiccant, and oxygen absorber to convert hydraulic oil reservoirs from “open vent” breather systems to a “closed vent” system where the bladder accommodates system displacement. Air in the system passes through a heat pipe, desiccant dryer and oxygen absorber, removing moisture and oxygen and preventing corrosion.

Remote Mount System

Video coming soon!

Introducing - A new technology for Protecting Hydraulic Oil and Gear Boxes. U.S. Patents and patent pending.

Don’t just treat the problem, eliminate the source of the problem!

The Benefits of Using a Closed System Hydraulic Breather

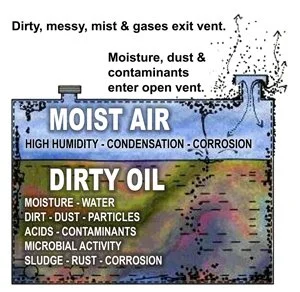

Open hydraulic oil systems allow airborne contaminants including dirt, moisture and oxygen to enter system through the breather vent port. This causes oxidation of oil, high humidity, condensation, free water accumulation, emulsified oil, sludge and acid formation and corrosion. This results in frequent oil and filter changes, high operating costs, downtime and shorted equipment life. Oil contamination causes over 85 percent of all hydraulic system failures.

OILN2 keeps hydraulic oil and equipment clean, dry and blanketed in a high concentration of nitrogen thereby stopping oil oxidation.

Thermal conduction rod technology in combination with an oxygen / desiccant cartridge depletes the oxygen and moisture within the reservoir air chamber.

OILN2 creates a closed, dry nitrogen filled environment above the oil surface 24/7.

OILN2 extends life of oil, filters and equipment. Substantially reduces operating and maintenance costs. It also reduces environmental contamination – a GREEN product.

Each OILN2 unit is a complete closed unit with a thermal conduction rod, heat rejection head, replaceable oxygen eliminator and desiccant dryer cartridge, variable volume device, excess pressure and vacuum relief valve housed in a wall mounted lightweight HDPE housing.

OILN2 installs with one simple connection to the breather vent port of the oil reservoir. This replaces the vent cap and automatically converts the system from “Open” to “Closed”. Spin-On and Remote mounted units available.

Once installed on a clean dry system OILN2 may last for years without the need to change out the replaceable cartridge.

OILN2 can be provided for virtually any hydraulic oil or gear box from 1 to 1,000 gallons. Use selection chart or contact IRI for suggested size.

Result: With OILN2 installed frequent oil and filters changes become a thing of the past. When the oil filter is changed, consideration can be given to a much higher efficiency filter .

Fast turnaround for OILN2 units for reservoirs sizes up to 200 gallons.

Typical Pay-Back should be far less than a year and may only be a few months.

OILN2: a sustainable add-on oil protection apparatus.

OILN2 converts hydraulic oil reservoirs from “open” breather vent systems to “closed” systems with an expandable bladder that acts like a lung keeping the internal air chamber sealed. The conduction rod and associated cartridge attracts and captures internal oxygen and water. As the oxygen is depleted the inert dry nitrogen gas concentration increases and blankets and protects the oil from oxidation. This results in clean dry oil making frequent oil and filter changes a thing of the past.

Sealing the system “closed” keeps out all the airborne contaminants.

It alters the internal environment to a clean dry nitrogen filled state.

No more frequent oil changes.

No more frequent filter changes.

Less downtime.

Less operating and maintenance costs.

Equipment life is extended.

OILN2 is ideal as a protector from high humidity areas, dusty and dirty conditions, and wash-down areas.

OILN2

For hydraulic oil systems. Patented and patent pending.

Covers oil surface with nitrogen – helps prevent oil oxidation.

Converts “OPEN” Systems into “CLOSED” nitrogen filled Systems.

Extends life of oil, filters and equipment.

Prevents oil oxidation.

Prevents outside ingression

Converts system to “Closed”

Protects environment.

Simple - one connection.

Low cost.

Hydraulic tank filler breather replacement

May outperform other desiccant breathers by creating a closed, dry, nitrogen-rich environment.

Typical pay back -

LESS THAN ONE YEAR!

OILN2 installs at the breather port and alters and maintains the interior environment to create a clean, dry, high nitrogen concentration environment. An internal conduction rod and cartridge attracts and captures oxygen and water and alters the interior environment to a high nitrogen concentration. Reduces oxidation of the oil with all the sludge and damaging corrosive action that causes downtime and shortens equipment life.

DON'T SETTLE FOR A DIRTY SYSTEM.

Oxidation of oil

Free water problems

Emulsified water

Condensation

Contaminated oil

Sludge and corrosion

High wear and tear

Frequent oil & filter changes

High O & M costs

Downtime and system failure

Environmental pollution

Applications:

Hydraulic reservoirs, gear boxes, presses, oil and lubrication tanks, autos & trucks, cranes, lifts & earth moving equipment, industrial, factories, manufacturing, processing equipment, & robotics, marine, mining, military, transformers, windmills