Sustainable Biomass Solution with CNFbiofuel™ Pellets

Inventive Resources, Inc. is in the design and development stages of building a pilot biomass torrefaction processing plant.

Current design is for laboratory size production rates for testing and evaluation. Later pilot designs include production rates or 3 tons per hour and up to one ton of processed fuel per minute.

CNFbiofuel™ pellets

Made from biomass*, in pellet form, that has all the positive qualities required to finally help solve our energy and pollution problems.

CNFbiofuel™ is a clean burning product that was once wood, but processed in a unique way that removes virtually all the water and polluting volatile organic compounds before combustion.

The wood is processed in a proprietary manner that changes the chemistry and structure of the wood into a friable material that has a high carbon content that can be used with coal or to replace coal.

Every ton of carbon in CNFbiofuel™ used will keep 3.6 tons of carbon dioxide from fossil fuel out of our air. CNFbiofuel™ is resistant to water absorption and can be stored indefinitely without decay.

*Biomass includes all forms of plant matter such as grasses, trees, agricultural prunings and waste, animal waste, forest debris, algae, lumber waste, paper pulp etc. Dry wood may have a heat content of 8,000 Btu/pound. CNF torrefied wood™ may have a heat content of 10,000 Btu/pound.

HISTORY

A new patented process has promise in helping solve the global energy and pollution problems caused by fossil fuel use with a clean form of biomass fuel. This new process makes the collection and processing of biomass and solid waste into a useful fuel practical to provide clean electric power. We in the USA, at only 5% of the world’s population, can reduce Use, Conserve, Recycle, Change Processes, & Develop new Technologies. However, with developing nations demanding more energy to grow their economies, it will be very difficult to keep up with the growing energy demands with resultant pollution no matter what we do here in the USA. Some nations are using very dirty coal and oil and we receive the pollution. Some nations are adding one coal fired power plant every week. Not only do we need to find clean energy solutions we need to educate and export this technology to other countries, and we need to do it soon with near term solutions.

What is fuel made from? Fossil fuel natural gas and oil have much in common with all forms of biomass including plants, wood, solid waste paper & cardboard, animals and people. The common elements are carbon & hydrogen. They are all referred to as hydrocarbons with different combinations of C & H. The main products of complete combustion of hydrocarbons are Energy, Water and Carbon Dioxide. However, complete combustion rarely occurs when biomass is burned, due to the contained moisture and volatile gases that result in considerable pollution. That is why it is not used extensively. Wood in a fireplace may appear dry but may contain 26% moisture.

Problem:

Energy & Pollution The equivalent level of carbon mass taken out to the ground each year, for energy production, and put into our ecosystem is enormous. Over 8 billion tons of fossil fuel carbon is used each year. If the carbon mass were stacked on a football field it would extent over 400 miles high. These 8 billion tons of carbon, when burned, generates over 22 billion tons of carbon dioxide gas or 400 trillion cubic feet in volume, plus other GHG’s and heavy metals, radioactive material and other toxic substances. The bulk of this pollution remains in our atmosphere for many years. This is something we should be concerned about. Most discussions on global warming and climate change refer to carbon dioxide concentrations. The atmosphere near earth’s surface is mainly Nitrogen 78%, Oxygen 21%, Argon 1%. These three add up to 99.96%. All other gases are less than 0.04%. Carbon Dioxide is now at 0.0387%. The carbon dioxide concentration has increased from 265 ppm to over 387 ppm due to fossil fuel use. We need to address this as a global energy and environmental pollution problem. California generates hundreds of millions of tons of solid waste each year. This includes municipal trash like paper and cardboard, waste wood, forest residue, agricultural waste including prunings and animal waste. When left to decay or decompose in landfills the stored suns energy is lost and we gain the pollution in the form of methane, carbon dioxide and many other GHGs. Most biomass and solid waste to energy conversion methods are very energy inefficient and only a very small percentage of solid waste is used for energy.

Solution:

Up until now the only practical near term solution to our global energy problem is the sun. We need to look at available biomass and solid waste as a natural resource and turn it into a solution instead of a problem. Trees absorb carbon dioxide - the main greenhouse gas. One acre of trees can absorb as much as 4 tons of carbon dioxide a year, the same amount as a car driven 26,000 miles. Energy crops such as Switchgrass may produce over 10 tons of useful biomass per acre. What is needed is a clean burning form of biomass that can replace fossil fuels, mainly coal, which is the dirtiest and cheapest fossil fuel. Here in California, the gasification of biomass can have many benefits because almost half of the electric power we use is produced by natural gas. Wood contains moisture and VOC’s and absorbs water from the air. Moisture leads to incomplete combustion when burned and generates many undesirable GHG’s. All types of biomass have not been in a clean burning form. Biomass from energy crops, forests residue, agricultural waste, waste wood and solid waste has a bulk density of 10 to 15 pounds per cubic foot. This bulkiness makes handling, transport and use impractical. Wood pellet mills can now quickly densify and efficiently produce pellets at 40 to 70 pounds per cubic foot and that greatly reduces transporting costs. However, all wood biomass is still hydroscopic and when supplied to power plants is non uniform and high in moisture and results in poor performance. Paper, cardboard and waste wood account for most of the recoverable solid waste and may be converted into a useful carbon neutral fuel instead of being a disposable waste product.

-

TORREFACTION

At high temperatures an endothermic reaction changes the structural and chemical composition of biomass.

-

PROCESSING SYSTEM

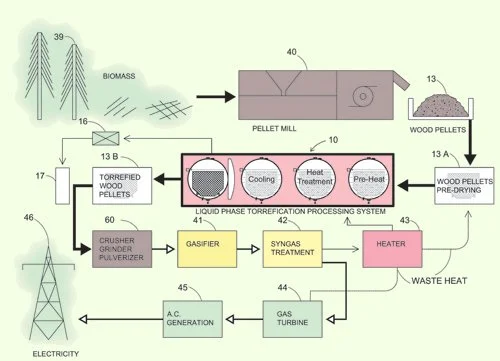

New patent pending process changes biomass into the perfect solid fuel.

-

U.S. POWER GENERATION

CNFbiofuel™ has the potential to eliminate our dependence on fossil fuels.

NEW PROCESS

PRIOR ART

Even though torrefied wood was originally developed decades ago very little has ever been used for energy production. Most prior art processing methods used to make torrefied wood used “Convection” heat treatment. Biomass was exposed to hot gasses in a low oxygen chamber. Hot combustion gasses and or steam at up to 600 psi are used for heat transfer. Power plants complaints include non-uniform product and high cost. Less than 1% of biomass is used for energy production.

NEW PROCESS

The CNFbiofuel™ system uses a new patented Liquid Immersion Torrefication Processing Technology. This uses “Conduction” heat treatment of wood pellets in multiple stages of heat transfer fluid. This process puts over 1000 times as many molecules in direct contact with the wood surface as compared to the prior art “Convection” heat treatment in a gas or steam process.

Preliminary testing of CNFbiofuel™ has shown positive results in increased heat content, friability and hydrophobic properties making it an ideal fuel. The produced fuel is ideal for solid fuel, atomization or a uniform feedstock for gasification.

CNFbiofuel™ has multiple patents pending on “Conduction” heat treatment. These include continuous flow and batch processing. Wood pellets are exposed to a series of “conduction” heat treatments temperatures that include Pre-Heat, Heat Treatment and Cooling. The advantage of this technology is that it puts 1,000 times as many heat transfer molecules in direct contact with the wood surface over convection methods. This results in faster and more efficient processing.

Biomass is first treated in the Pre-Heated with immersion heat transfer fluid at 300ºF. This drives out the moisture in the biomass. This moisture in the form of steam exits the system and is exhausted outside.

The biomass is then Heat Treated in immersed heat transfer fluid at 480ºF. This is where the VOC’s and any remaining moisture are driven out of the biomass. All the emissions are routed through a condenser where certain reclaimable liquids are captured. During this phase, the biomass is heated in an oxygen free environment and becomes torrefied. The biomass composition continues to take in heat without a change in temperature. This is the endothermic reaction phase where torrefaction occurs. The cellular structure and chemical composition changes during torrefaction.

The hot torrefied biomass is then Cooled in a heat transfer fluid at close to 300ºF. This cools the torrefied biomass to a safe temperature where combustion cannot occur. (Note: Wood can combust or oxidize when exposed to high heat treatment temperatures in air or in the presence of oxygen.) The torrefied biomass then exits the Cooling section where the torrefied biomass is air cooled and further draining of the heat transfer fluid occurs. The drained heat transfer fluid is captured and re-used in the process.

The heat transfer fluid is a paraffinic base material that has a very low vapor pressure at 480ºF. The vapor pressure at this condition is less than a two inch water column. Other plant based heat transfer fluids at higher vapor pressures can also be used in the process. The entire processing operation occurs at relatively low pressures and that reduces construction costs. The heat content of the heat transfer fluid is over 18,000 Btu per pound. The torrefied biomass does contain a small amount of heat transfer fluid and this enhances the heat content by the amount of heat transfer fluid on and within the treated biomass.